Roll clad plates allow the combination of a low-cost base material and a corrosion-resistant cladding material. Applications range from chemical apparatus engineering, gas and oil industry to seawater desalination plants. Various quality problems can occur in production, with delamination being the most common type of damage. In this case, the two layers become detached, resulting in a two-dimensional separation. In order to detect such quality problems at an early stage and avoid them as a result, it is important to apply the right procedures and controls during the manufacturing process.

Thermal tomography based on the mobile and smart voidsy 3D V-ROX sensor offers a cost-effective alternative to the currently very costly ultrasonic technology. The steel sample shown has a size of 100x100x60mm³, where the thickness of the contact steel was 3mm. The defects found by ultrasound were marked by hand on the sample surface by black rectangles.

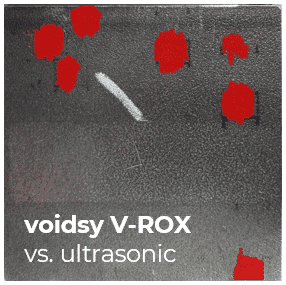

A comparison between the commercially used ultrasound, the state-of-the-art thermography in the form of a pulse-phase evaluation (PPT) and the virtual C-scan shows very clearly the advantages of the voidsy V-ROX system. Due to the high spatial and depth resolution of the voidsy V-ROX system, all delaminations could be correctly identified in position and size. The high signal-to-noise ratio allowed segmentation of the defects.

The overlay of the segmented voidsy V-ROX results with the ultrasound defect pattern shows the good agreement between the two methods and also the higher sensitivity of the V-ROX system.

voidsy gmbh | Magazinstraße 18, 4600 Wels, AUSTRIA | [email protected] | Company registration: FN 587365 y | Managing Director: Dr. Holger Plasser

We´re closed from December 24, 2025, to January 7, 2026, as we take time to celebrate Christmas and ring in the New Year.

We wish you a Merry Christmas and a wonderful start to 2026!