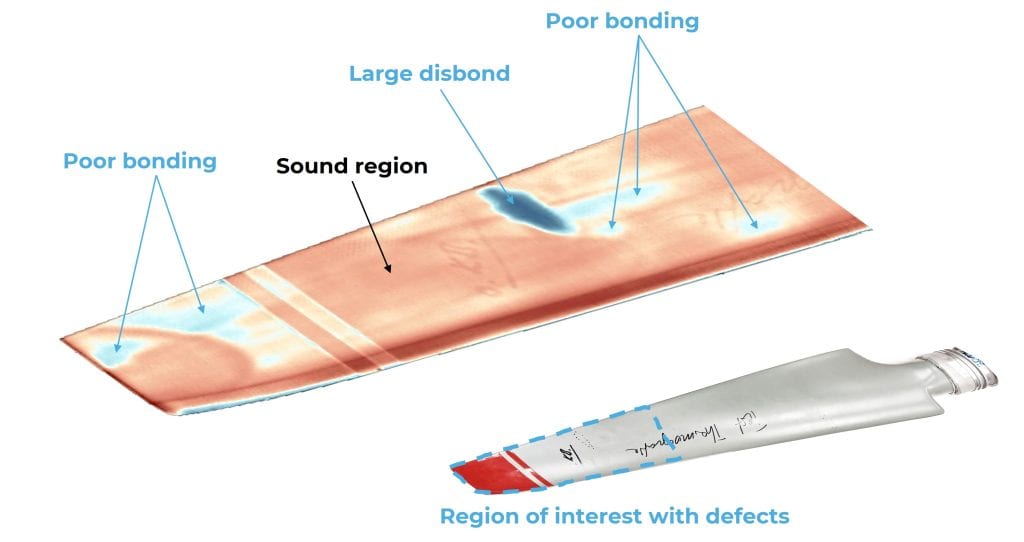

A wide variety of defects can occur in propeller blades that can impair performance and safety during operation. These include, for example, major delamination or poor bonding quality of the composite surface layer with the core material. These can occur both during production and as a result of external loads during operation. In order to detect defects reliably and quickly, it is necessary to use non-destructive and imaging testing.

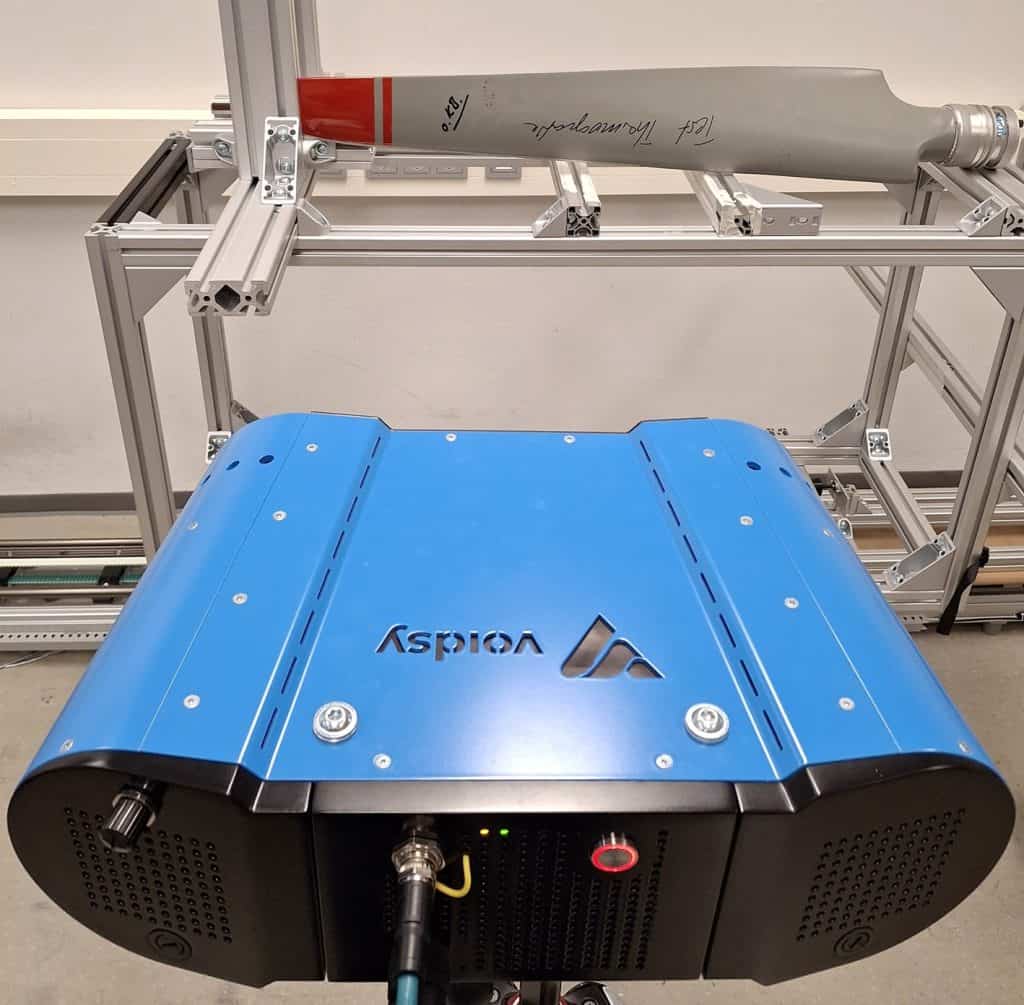

The voidsy 3D V-ROX was used successfully for the first time to inspect propeller blades with different core materials. This non-destructive technology made it possible to reliably localize and determine the size of damage.

The measurement took less than 10 seconds with a spatial resolution of 700 µm. The high sensitivity of the system enabled the precise identification of defects, while the imaging analysis allowed easy interpretation and documentation of the results.

This advanced technology offers an efficient and mobile solution that makes it possible to quickly inspect propeller blades in the field, even under load tests. Our expertise in non-destructive quality assurance supports the aviation industry in ensuring the high safety standards and reliability of propeller blades.

voidsy gmbh | Magazinstraße 18, 4600 Wels, AUSTRIA | [email protected] | Company registration: FN 587365 y | Managing Director: Dr. Holger Plasser